Biosecurity Guide for Fruit and Tree Nut Producers

March 31, 2017

Contents

- Glossary

- Preface

- How to Use this Guide

- 1.0 Introduction

- 2.0 How to Create a Plan and Implement Biosecurity Measures

- 3.0 Develop Your Plan

- 4.0 Communication, Education and Training

- 5.0 Site Assessment: Geography, Location and Layout

- 6.0 Conclusion

- Appendix 1: Example of a Pest Introduction Pathway Analysis

- Appendix 2: Example of a Sign Used to Limit Access to Restricted Areas

- Appendix 3: Acknowledgements

Glossary

The following terms are used in this Producer Guide. In the section in which each term is most relevant, the term is linked to this glossary.

- Action threshold

- A point at which pest populations, economic considerations or environmental conditions indicate that pest control action must be taken.

- Biological control

- Biological control is a component of an Integrated Pest Management (IPM) strategy to reduce pest populations through the use of natural enemies such as predators (e.g. predatory mites), parasitoids (e.g. wasps), and pathogens (e.g. bacteria).

- Biosecurity

- A series of management practices designed to reduce the introduction of pests onto a farm (bioexclusion) and to minimize their spread within the farm and beyond (biocontainment).Footnote 1

- Biosecurity Plan

(also called "Plan" in this document) - A written procedure of practices designed to prevent, minimize, control, and contain pest movement onto, spread within and off a farm. The Plan is farm-specific.

- Clean

- To physically remove visible dirt and debris that may harbour pests. Cleaning does not necessarily result in the physical destruction, killing or removal of pests. It is important to recognize that the degree of cleanliness required and the methods employed will depend on the pest itself, its route of transmission and the surfaces being cleaned. In some instances, the removal of visible dirt/debris should be followed by the use of disinfectant or sanitizer to properly control the pest of concern.

- Disinfect

(application of a disinfectant) - The process that is used to inactivate, decrease or eliminate a pest from a surface or an object. The use of a disinfectant may require additional personal precautions to minimize safety concerns associated with application of the product.

- Emergency Response Plan

- A plan that describes actions to be taken in the case of a major event (likely pest-related) that may threaten to harm a farm.

- Farm

- A tract(s) of land used for the purposes crop production. The farm includes residences and all storages, buildings, and structures, as well as fields (including those remotely located) used to produce a crop.

- Infested area

- Presence in an area of a living pest of the plant or plant product concerned. Infestation includes infection.Footnote 2

- Integrated Pest Management (IPM)Footnote 3

- Integrated Pest Management (IPM) involves the use of several control tactics based on knowledge of the crop, pests and associated natural enemies to avoid crop loss and minimize harmful effects on the environment.

- Life cycle

- The series of changes occurring in an animal or plant between one development stage and the identical stage in the next generation.

- Monitoring program

- A scheduled activity to look for the presence or signs of pests. This may include: observation of plants, fruits and nuts; trapping; and sampling and testing of plant material. The frequency of this activity depends on the time of year, the life cycle of the pests of concern and level of risk.

- PestFootnote 4

- Anything that is injurious or potentially injurious, whether directly or indirectly, to plants or to products or by-products of plants, and includes any plant prescribed as a pest, insects, diseases, viruses and weeds.

- Protocol

- A code of correct conduct or a standardized set of procedures or practices when implemented in sequence are designed to achieve a specific objective.

- RepackingFootnote 5

- Includes:

- Removing market product from its market-ready packaging materials, re-handling the product (e.g. re-sorting, re-grading, re-trimming, re-washing, re-fluming), and putting it into market-ready packaging materials. Product may also be combined with other product that differs in some way (e.g. type, origin, timeframe).

- Activities (e.g. icing, labelling/coding, cooling) that occur once the product is in the packaging materials.

- Response plan

- A set of protocols to prepare and respond to a pest problem that allows for a rapid response to the introduction.

- Sanitize

(application of a sanitizer) - A process that reduces the number of pathogens without completely eliminating all microbial forms on the surface.

- Visitors

- In this document, the term "visitors" includes any people other than employees who enter a farm, such as suppliers, service providers and customers.

Preface

This Biosecurity Guide for Fruit and Tree Nut Producers (the Guide) has been developed as a supporting document to Developing Your Biosecurity Plan: The National Voluntary Farm-Level Biosecurity Standard for the Fruit and Tree Nut Industries (the Standard) to assist producers with the development of a Biosecurity Plan (a Plan) for their farms. This Guide is voluntary and provides best practices and biosecurity measures for consideration to help producers achieve the biosecurity and pestrisk mitigation goals identified in theStandard.

Producers should establish priorities for implementing biosecurity measures for their farm, as it is understood that not all biosecurity measures will apply to each commodity or farm. In addition, applying all biosecurity measures in this Guide may not be cost-effective.

This Guide applies to a diverse group of fruit and tree nut farms. Not all biosecurity measures included in this Guide may apply to each commodity or farm. To develop an effective Plan for your farm, you must identify the pests of concern and analyze their pathways of transmission for your specific commodity and place of production.

This Guide does not address risks and concerns related to food safety and quality. These are covered by regulations and programs such as HACCP.

How to Use this Guide

i) Organization of this Guide

This Guide has been organized into the following sections:

- Develop your Plan

- Assessment

- Identification

- Pathways of Transmission

- Living organisms

- Inputs

- People

- Vehicles, Tools and Equipment

- Outputs

- Pest Monitoring Program and Response Plan

- Communication, Education and Training

- Site Assessment: Geography, Location and Layout

These sections are each divided into three parts:

- Target outcome: Goals that all producers of fruit and tree nuts should try to achieve to protect their plants from the introduction and spread of pests.

- Benefits: Details regarding why a specific target outcome is important to biosecurity.

- Checklists: Guidance and biosecurity measures to consider to help minimize pest risk. The intent of the biosecurity measures is not to prescribe but to provide guidance. The biosecurity measures are based on an understanding of pest risk, pathways of transmission, science and management practices. Measures need to be attainable and practical.

Various examples of how the information in this Guide may be applied are presented in green text boxes. These examples are presented for illustration purposes only.

Appendices at the end of the Guide provide producers with examples of tools that can be used to implement biosecurity measures.

ii) How to Complete the Checklists

The checklists have been provided to assist producers in assessing risks and defining biosecurity measures for their farm. There are four columns included in the checklist to indicate whether a biosecurity measure has been implemented (Yes), if it is sometimes implemented (Sometimes), if it is not implemented (No) or if it is not applicable to the farm (Not applicable).

iii) Self-Assessment Checklist and Action Work Plan PDF Document

The Biosecurity Guide for Fruit and Tree Nut Producers Self-Assessment Checklist and Action Work Planrepeats the checklists from the Guide in an interactive format. This tool also includes a work plan where actions to implement additional biosecurity measures within a farm can be recorded. When the tool is completed electronically, the biosecurity measures for which "No" and "Sometimes" are chosen are automatically transferred to the action work plan. This tool can be downloaded from the forms catalogue on the Canadian Food Inspection Agency's website. In the "Filter items" search field, type "5802" to obtain the form.

1.0 Introduction

Biosecurity is a set of practices used to prevent, minimize and manage the transmission of pests, including their introduction, spread and release. Implementing and enhancing biosecurity measures within a farm helps protect the individual and sector-wide economic interests. Producers benefit from awareness of the risks and of the measures that can be implemented to minimize pest introduction and spread.

Implementing biosecurity measures can be effective not only for mitigating the spread of pests but also to prevent the introduction of new and unknown pests. Developing and implementing a Biosecurity Plan in a farm depends on an analysis of the risks and pathways of pest transmission. With this knowledge, pest vectors can be managed and biosecurity measures can be applied to interrupt pathways of pest transmission, thereby reducing crop damage and minimizing economic losses. Examples of pathways of transmission include insects, employees, equipment and wind.

Example: Potential impacts of blueberry maggot (Rhagoletis mendax)Footnote 6

Blueberry maggot (BBM) is a regulated pest for Canada and is a serious pest in eastern North America. Direct costs include reduced fruit yield and quality due to larval feeding and increased costs related to pest control. In addition, there are indirect costs related to certifying fruit for export to countries that regulate BBM. A Plan can include measures to prevent the introduction and spread of BBM within a farm.

Within the fruit and tree nut industries, biosecurity standards and programs support Canada's reputation as a safe and reliable trading nation. This has positive economic, environmental and community benefits for all Canadians.

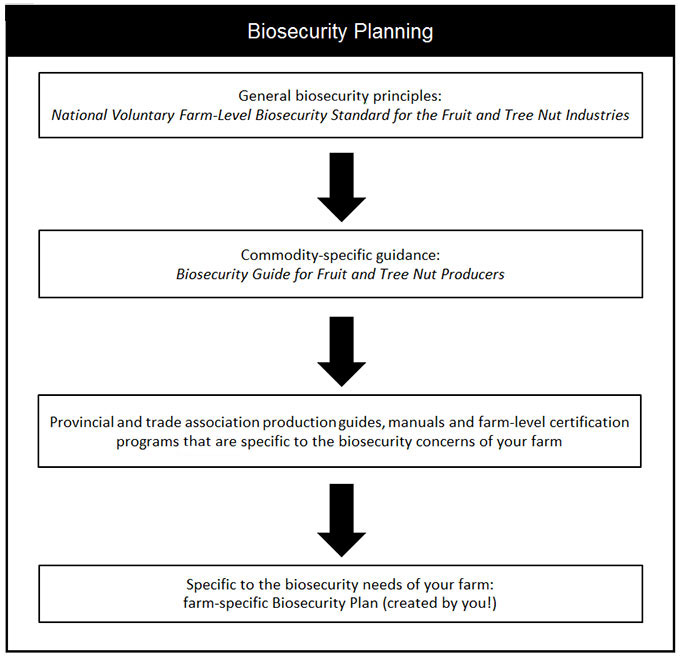

The Standard and this Guide provide guidance for the development of individual Plans that enhance but do not supersede existing farm-level programs, such as CanadaGAP® and other regional or provincial programs. Figure 1 shows how, together, these documents and tools can support the development of farm-specific Plans.

Description for image – Flow chart of how the Standard, the Guide, regional or provincial programs, and existing farm-level programs can together help you develop your Plan

The title of the image is "Biosecurity Planning". It is a flow chart with four boxes arranged in a column, with arrows between each box pointing down. Each box has text written inside. Starting at the top, the text in the first box states: "General biosecurity principles: National Voluntary Farm-Level Biosecurity Standard for the Fruit and Tree Nut Industries". The text in the second box sates: "Commodity-specific guidance: Biosecurity Guide for Fruit and Tree Nut Producers". The text in the third box states: "Provincial and trade association production guides, manuals and farm-level certification programs that are specific to the biosecurity concerns of your operation". The text in the fourth box states: "Specific to the biosecurity needs of your farm: farm-specific Biosecurity Plan (created by you!)".

Benefits of a Plan

Developing a Plan defines, formalizes and documents many of the risk reduction measures already in place at your farm and helps identify potential biosecurity gaps. A Plan supports the prevention rather than management of pest introduction and spread, which is less costly. If a pest is detected, rapid response protocols are already in place, reducing the damage and spread of pests. A Plan can also help educate new employees and visitors about the biosecurity risks and measures at your farm. Other benefits of incorporating biosecurity measures into the day-to-day activities of a farm include:

- Avoiding new pest introductions.

- Containing infestations and minimizing the impacts of pests that are already present.

- Breaking the cycle of transmission of pests from one farm to another, to the wider community and between trading partners.

- Reducing production losses.

- Managing the risk of business interruptions as a result of pest detections.

- Meeting customer and consumer demand for biosecurity measures and protocols.

- Attracting new markets.

It is preferable to prevent rather than manage the introduction or spread of a pest within a farm.

2.0 How to Create a Plan and Implement Biosecurity Measures

The Standard describes a series of target outcomes that focus on mitigating the risk of pest introduction and spread in production facilities. This Guide is intended to help producers develop farm Plans to support these target outcomes, including assessing biosecurity risks to their farm and identifying biosecurity measures that can be implemented to mitigate these risks.

The Standard and Guide include self-assessment checklists to help producers define and document existing biosecurity measures and identify biosecurity gaps at their farm. The Biosecurity Guide for Fruit and Tree Nut Producers Self-Assessment Checklist and Action Work Plan includes an action work plan where actions to complete the implementation of additional biosecurity measures within a farm can be recorded.

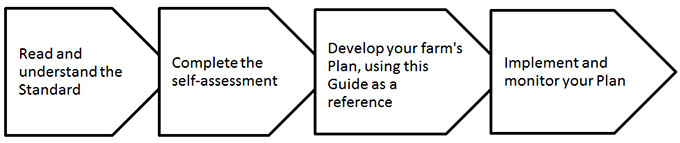

Description for image – How to Create a Plan and Implement Biosecurity Measures

There are four arrows in a row. Each arrow has text written inside. From left to right, the text in the first arrow states: "Read and understand the Standard". The text in the second arrow states: "Complete the self-assessment". The text in the third arrow states: "Develop your farm's Plan, using this Guide as a reference". The text in the fourth arrow states: "Implement and monitor your Plan".

Developing and implementing your Plan can be seen as a cycle of activities:

- Assess pest risks and reassess on a regular basis to ensure preparedness.

- Develop a Plan to address biosecurity risks.

- Implement measures, procedures and practices.

- Monitor the effectiveness of the Plan and modify as necessary.

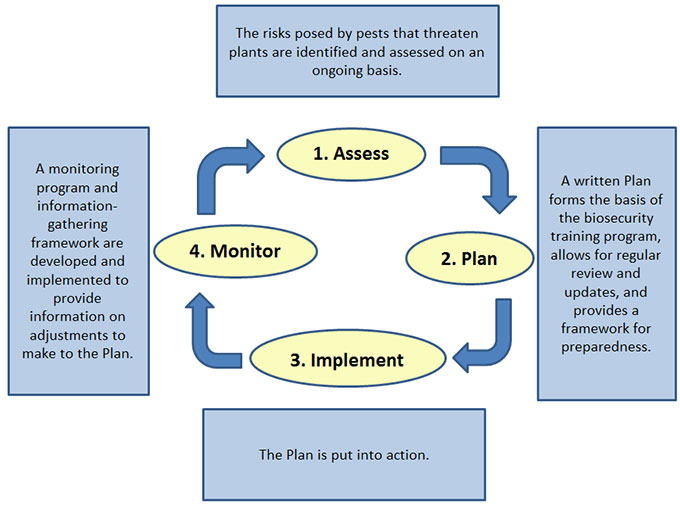

Figure 2 shows the cycle of biosecurity activities, where pest risk assessment and reassessment are both the beginning of the cycle and the renewal of the cycle. This is a dynamic process of continual assessment to ensure the process is effective.

Description for image – The biosecurity planning cycle

Figure 2 is an illustration of the cycle of activities that should be completed to develop and implement a Biosecurity Plan. The cycle of biosecurity has four items with arrows pointing between them in a clockwise direction. The first item at the top of the cycle is "Assess". Moving clockwise, the second item is "Plan", the third is "Implement" and the fourth is "Monitor". There is a text box by each of these four items in the cycle. The text box by the word "Assess" states: "The risks posed by pests that threaten plants are identified and assessed on an ongoing basis." The text box by the word "Plan" states: "A written Plan forms the basis of the biosecurity training program, allows for regular review and updates, and provides a framework for preparedness." The text box by the word "Implement" states: "The Plan is put into action." The text box by the word "Monitor" states: "A monitoring program and information-gathering framework are developed and implemented to provide information on adjustments to make to the Plan."

Assess: Identify and assess pest introduction risks and analyze probable transmission pathways. This allows producers to assess available control measures and develop appropriate biosecurity measures. Production practices should also be reviewed regularly (reassessed) to ensure that the implemented measures are effective.

Plan: A written Plan is highly recommended. A written Plan allows for regular review and update, supports preparedness within the farm and forms the base for training. A Plan may consist of a detailed map of the farm, description of farm policies, and written procedures or protocols that describe the biosecurity measures in place. These written procedures could be organized based on the categories presented in this Guide or by activities that make sense to the producer. The Plan should include the implementation of a monitoring program to identify pests that may be introduced to the farm. The Plan will vary from one farm to another depending on factors such as crops grown, geographic location and farm size. The Plan should be reviewed and updated regularly as new pests emerge, as new biosecurity information becomes available or if there are changes to the farm.

Implement: Put the Plan into action. Education, training and communication are key to effectively implementing the Plan.

Monitor: Create an information-gathering system that identifies emerging pest risks for the farm. Regularly assess whether biosecurity measures result in the prevention, early detection or elimination of pest threats. Identify biosecurity gaps that may have allowed a pest incursion, determine whether the introduction could have been prevented and identify possible mitigation measures. It is important to assess the design, effectiveness and implementation of the Plan routinely, but also when there are changes in farm practices or biosecurity threats.

3.0 Develop Your Plan

3.1 Assessment

Your Plan should include a process to identify the current and potential pest risks to your farm as well as the probable pathways of transmission (see section 3.3). Try to answer the following questions using the elements identified below:

- Which pests pose a critical threat to your farm?

- What is the pathway of transmission and likelihood of introduction into your farm for each of these pests?

- What are the critical points where you can apply biosecurity interventions to mitigate the risks associated with these pathways of transmission? For example, can you designate certain areas on your farm for specific activities (e.g. receiving inputs, parking, cleaning equipment, disposing of infested material) to prevent pest introduction and spread?

- If a pest is introduced into your farm, will there be impacts on your crop, your plants, the environment, or your neighbour's farm? What are the potential impacts?

- If a pest is detected or becomes established on your farm, will there be impacts on the marketability of your crop? Will existing markets close, or will the opening of new markets be delayed or halted?

- Could quarantine restrictions prevent the movement of your crop?

- Do you have the tools to control the pest if it is introduced into your farm (e.g. knowledge of the pest, understanding of its pathways of transmission, effective sanitation programs, biological or chemical controls)?

The following elements may help you assess the pest risks for your farm:

1. Information resources

The following resources can provide current information on topics such as emerging pest risks:

- Local agrologists, extension workers, researchers, fellow producers, producer associations.

- Local horticulture publications.

- Industry meetings.

- Pest identification and monitoring at your farm.

Online information sources

The internet is a valuable source of information for developing your Plan. Some examples of online resources include:

- Pest bulletins (provincial agriculture departments, Canadian Food Inspection Agency website).

- Local horticulture websites.

- Research reports.

- Industry horticultural bulletins and articles.

- Internet-based provincial production guides for your region/commodities.

2. Requirements and regulations

Federal, provincial and municipal government resources can provide information on:

- Regulations and changes to regulations.

- Specific criteria in other farm-level programs (e.g. Integrated Pest Management or CanadaGAP®).

- Requirements for market access that may be more stringent than regulations.

3. Environment

Pests may be introduced to your farm from the local environment. Factors to consider include, but are not limited to:

- Neighbouring land use and production practices.

- Direction of prevailing winds, natural barriers and drainage.

- Alternate hosts, such as the natural vegetation within and surrounding the farm.

- Climate.

- Traffic, proximity to high-traffic routes, local commerce (e.g. produce markets).

- Contaminated water sources.

4. Layout

Understanding the layout of your farm helps identify movement patterns and potential pest transmission pathways.

- Create a map of your farm, including designated areas, to help train new employees, plan future production processes and manage pest detections.

- Identify specific routes for the movement of inputs, people, vehicles, equipment and outputs.

Gathering information is an ongoing process that allows you to adjust your Plan to mitigate risks as they are identified. There may also be biosecurity protocols at regional, provincial or national levels that could be integrated into your farm-level biosecurity program.

3.2 Identification

There are many insects, nematodes, viruses, bacteria, phytoplasmas, fungi and weeds that can impact fruit and tree nut crops. To effectively control or contain a pest, it must be correctly identified and its pathways of transmission must be understood. Proactive biosecurity measures applied at critical points in the pathways of transmission can prevent introduction and limit the spread of pests. You can get help with pest identification and information on pathways of transmission from pest consultants, provincial and federal agencies, industry researchers and academia.

When developing your Plan:

- Be aware of emerging pests.

- Identify the pest risks to your farm.

- Be familiar with the pest status of the region receiving your crop.

- Determine if a pest should be part of your pest monitoring program.

- For each pest of concern, understand the pest life cycle, including its stages of development and the signs and symptoms of each stage.

- Develop protocols for correctly identifying pests and determining the most appropriate and effective controls.

3.3 Pathways of Transmission

Pathways of transmission can introduce and spread pests into and within your farm and, in the case of outputs, spread pests from your farm to other areas. Some examples of pathways include living organisms, inputs, people, vehicles, tools, equipment and outputs. These categories are described below in sections 3.3.1 through 3.3.5.

Example: Analyzing the pest transmission pathways at your farmFootnote 7

The following is an excerpt from a larger table in Appendix 1, which provides an example of a pest transmission pathway analysis table:

| Plants | Soil, mulch | Air, wind | Water | People | Other pathways | |

|---|---|---|---|---|---|---|

| Viruses | X | aphids, bees | ||||

| Botrytis blight, gray mould (Botrytis cinerea) |

X | X | X | |||

| Bacterial blight (Bacillus subtilis) |

X | X | ||||

| Mummy berry (Monilinia vaccinii-corymbosi) |

X | X | X | X | bees |

Your Plan should aim to eliminate as many pathways of transmission as possible, since complete pest prevention is not always achievable. Knowledge and analysis of pest transmission pathways can help you identify potential controls and biosecurity measures that will mitigate pest risks and help break the cycle of pest transmission. Completing an analysis of the various pathways of transmission at your farm can help you prioritize measures to implement in order to first address the highest-risk pathways of transmission.

3.3.1 Living OrganismsFootnote 8

Target outcome:

Implementation of biosecurity measures at the critical points in the pathway of transmission of biological and mechanical vectors.

Living organisms can be a pathway of transmission and should be managed to prevent the introduction and spread of pests on your farm. The following are some examples of living organisms that can be pathways of transmission for pests:

- Viruses and bacteria can be introduced via insects.

- Birds and mammals can spread weeds via feet, feces and fur.

- Certain plants can be alternate hosts of pests that affect plants cultivated on your farm. Hawthorne, for example, is an alternate host for some apple pests. Removing alternate hosts or including them in your Integrated Pest Management program can be a critical step in your Plan.

Benefits

Managing living organisms that can introduce pests onto your farm can reduce crop damage, increase productivity and minimize economic losses.

Complete the following checklist to assess existing biosecurity measures at your farm or identify new biosecurity measures that should be incorporated into your biosecurity protocols. Indicate with a checkmark whether each biosecurity measure is:

- Yes (Y): Already in effect at your farm in all situations where it is appropriate.

- Sometimes (S): In effect, but not in all situations where it would be useful; would benefit from additional attention.

- No (N): Not in effect in any situation.

- N/A: Not applicable at your farm.

3.3.1 Biosecurity measures: Living organisms

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Wildlife and livestock are prevented from entering your production area. | ||||

| 2. Fencing or tree guards that wrap around tree trunks are used to minimize or deter wildlife from causing physical damage to your plants. | ||||

| 3. Pest vectors (e.g. aphids, leafhoppers, mealybugs, scales and nematodes) are managed with practices such as chemical, cultural and biological controls. | ||||

| 4. Crop rotation or fallowing of production areas is used to reduce the buildup of pests that can occur when one species is continuously grown in a production area. | ||||

| 5. Potential host plants within and around the production areas have been identified. | ||||

| 6. Control measures for these potential host plants have been implemented. | ||||

| 7. Production areas are located away from neighbouring crops that may be potential hosts of pests. | ||||

| 8. Compost piles are located away from production areas or are managed to reduce unwanted animals and pests. | ||||

| 9. Infested fruit, trees and plants are managed and disposed of to control pests. | ||||

| 10. Risks associated with pollen transfer and pollinators are considered. |

3.3.2 InputsFootnote 9

Target outcome:

To eliminate inputs as a potential source of pests.

Inputs such as nursery stock, compost, manure, fertilizer, mulch, soil, harvest containers, water and product from external sources can introduce and spread pests within your farm. For example, reusable containers and pallets may present a higher risk of introducing pests into your farm.

Benefits

Ensuring inputs are obtained from a reputable source (e.g. from a certified source or from a source that has implemented biosecurity measures) can reduce the risk of introducing pests to your farm.

Complete the following checklist to assess existing biosecurity measures at your farm or identify new biosecurity measures that should be incorporated into your biosecurity protocols. Indicate with a checkmark whether each biosecurity measure is:

- Yes (Y): Already in effect at your farm in all situations where it is appropriate.

- Sometimes (S): In effect, but not in all situations where it would be useful; would benefit from additional attention.

- No (N): Not in effect in any situation.

- N/A: Not applicable at your farm.

3.3.2 Biosecurity measures: Inputs

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Inputs that pose the highest risk have been identified and managed. | ||||

| 2. Inputs are sourced from reputable suppliers. | ||||

| 3. Inputs are received and stored in a designated area located away from production areas to prevent the spread of pests to plants. | ||||

| 4. Inputs are inspected for signs and presence of pests prior to accepting and moving them into production areas. | ||||

| 5. The receiving area allows for cleaning and treatment of inputs and of the receiving area. | ||||

| 6. Purchasing and production records are maintained for all inputs that pose a risk. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Nursery stock and budwood are purchased from a certified virus-free source, when available. | ||||

| 2. Pest resistance is one of the factors considered when selecting nursery stock. | ||||

| 3. Nursery stock is inspected for pests upon arrival and before planting. | ||||

| 4. Newly planted stock is monitored for pests (scouting). |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Testing histories or quality assurances are requested from compost and mulch suppliers to ensure they are not a source of pests. | ||||

| 2. Records of the location and date of use for compost and mulch batches are maintained (also required for food safety certification). | ||||

| 3. Raw manure is properly composted to reduce the risk of pest introduction. | ||||

| 4. The pest monitoring program includes areas where compost and manure has been applied. | ||||

| 5. Movement of soil from outside sources onto the farm is minimized and the risks of moving soil are considered. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. The source, availability and quality of the water applied to production areas are known. | ||||

| 2. Livestock and animals are prevented from accessing water sources used for irrigation or filling sprayers. | ||||

| 3. The water system is maintained, flushed and cleaned (disinfected or sanitized). |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Imported and domestically sourced product for packing and repacking are inspected for pests upon arrival in the packing facility. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. The risk of reusing harvest containers is considered. | ||||

| 2. Reusable harvest containers and transport containers are cleaned and stored in a designated area away from production areas. | ||||

| 3. An area away from sources of pest contamination has been designated specifically for the storage of clean packaging. |

3.3.3 PeopleFootnote 10

Target outcome:

Employees, visitors and service providers are informed and respect applicable biosecurity protocols.

The movement of employees and visitors into and within your farm can be an important pathway of pest transmission. Often people can move pests at a faster rate and reach a greater distance than natural means of spread. See also section 4.0 Communication, Education and Training for more information on how to mitigate biosecurity risks to your farm from people.

Example: People as a pathway of transmission for chestnut weevil

Chestnut weevil is devastating to chestnut farms. Once the weevil is introduced into a farm, it is nearly impossible to eradicate due to the weevil's life cycle and time of emergence.

The weevil is easily carried in dirt on footwear. If the weevil is present on your farm, you can avoid spreading it to other chestnut farms by not visiting them during harvest through to arrival of winter. If your farm is free from the weevil, make sure any visitors who may have been to potentially infested farms take appropriate biosecurity precautions. For example, you could lend them footwear that you know to be clean to wear during their visit.

Benefits

Managing the biosecurity risks associated with the movement of people between farms and within a farm can mitigate the risk of spreading pests that can be carried on footwear, clothing and hair.

Complete the following checklist to assess existing biosecurity measures at your farm or identify new biosecurity measures that should be incorporated into your biosecurity protocols. Indicate with a checkmark whether each biosecurity measure is:

- Yes (Y): Already in effect at your farm in all situations where it is appropriate.

- Sometimes (S): In effect, but not in all situations where it would be useful; would benefit from additional attention.

- No (N): Not in effect in any situation.

- N/A: Not applicable at your farm.

3.3.3 Biosecurity measures: People

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Visitors and employees who have been on other farms do not have soil or plant debris on footwear, clothing or hair. | ||||

| 2. Visitors and employees park in designated areas. | ||||

| 3. Visitors and employees only access areas necessary for their activities. | ||||

| 4. Hand-wash and foot-bath stations are provided at entrances and exits of production areas. | ||||

| 5. Access to restricted areas is limited to authorized employees only by using locks and gates and is highlighted by signage (see Appendix 2 for an example). |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Employees are trained in the biosecurity protocols of the farm (see section 4.0 for more information). |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Visible and appropriate signage is in place to inform visitors of biosecurity protocols. | ||||

| 2. Visitors report to the office or farm employees meet them in a designated area for a briefing on the biosecurity protocols. | ||||

| 3. Visitors are asked if they have visited another farm that day. | ||||

| 4. A visitor log is kept to record the date and areas visited. | ||||

| 5. The biosecurity risks posed by customers at a pick-your-own farm are assessed. | ||||

| 6. Anyone who has rights-of-way to your farm's land is briefed on your Plan and has agreed to abide by it. |

3.3.4 Vehicles, Tools and EquipmentFootnote 11

Target outcome:

Vehicles, tools and equipment are cleaned prior to entry and kept clean to prevent the introduction and spread of pests on your farm.

Vehicles, tools and equipment that are brought into and moved within your farm pose a biosecurity risk as they can be contaminated with soil and plant debris that can harbour pests. Non-agricultural vehicles and equipment that enter for activities not related to your production may also pose a pest risk. Examples include delivery vehicles, utility service vehicles, earth-moving equipment and gas exploration equipment.

Benefits

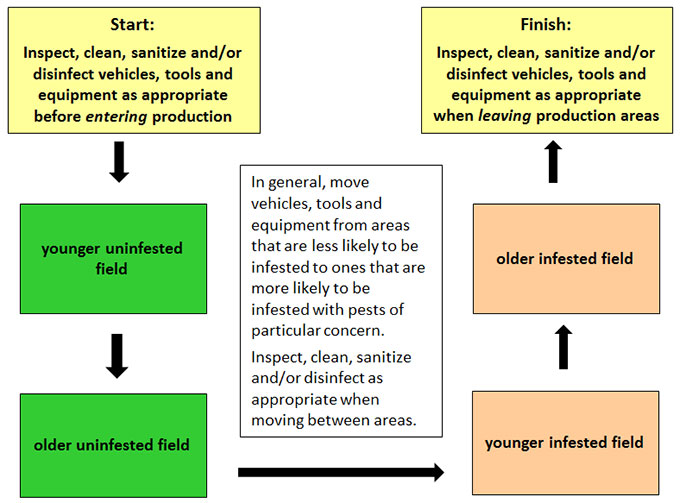

Biosecurity risks can be reduced by managing vehicles, tools and equipment entering and moving within your farm, including through cleaning, sanitizing and disinfecting as appropriate. Figure 3 shows an example of designated routes and cleaning requirements for vehicles, tools and equipment between production areas within a farm.

Description for image – Example of designated routes and cleaning requirements for vehicles, tools and equipment between production areas within a farm

The image shows a counter-clockwise arrangement of six text boxes linked with arrows. The first box, in the upper left corner, reads: "Start: Inspect, clean, sanitize and/or disinfect vehicles, tools and equipment as appropriate before entering production." The second box, at the middle left, reads: "Younger infested field." The third box, at the bottom left, reads: "Older uninfested field." The fourth box, at the bottom right, reads: "Younger infested field." The fifth box, at the middle right, reads: "Older infested field." The sixth box, at the top right, reads: "Finish: Inspect, clean, sanitize and/or disinfect vehicles, tools and equipment as appropriate when leaving production areas." In the middle of the circle, another text box reads: "In general, move vehicles, tools and equipment from areas that are less likely to be infested to ones that are more likely to be infested with pests of particular concern. Inspect, clean, sanitize and/or disinfect as appropriate when moving between areas."

Complete the following checklist to assess existing biosecurity measures at your farm or identify new biosecurity measures that should be incorporated into your biosecurity protocols. Indicate with a checkmark whether each biosecurity measure is:

- Yes (Y): Already in effect at your farm in all situations where it is appropriate.

- Sometimes (S): In effect, but not in all situations where it would be useful; would benefit from additional attention.

- No (N): Not in effect in any situation.

- N/A: Not applicable at your farm.

3.3.4 Biosecurity measures: Vehicles, tools and equipment

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Vehicles, tools and equipment are assessed for risk and, if necessary, inspected for soil, plant debris, organic material and insects and cleaned prior to entry and movement between production areas or designated areas. | ||||

| 2. An area located away from production areas has been designated for cleaning vehicles, tools and equipment. | ||||

| 3. Vehicles follow appropriate routes and established traffic flow patterns. | ||||

| 4. Vehicles move from lower-risk production areas to those more likely to harbour pests or that pose potential biosecurity risks. | ||||

| 5. Pruning and propagation tools are cleaned between areas where pest transmission is a risk. | ||||

| 6. Equipment and tools are cleaned to remove any soil and debris prior to disinfection. | ||||

| 7. Label directions are followed when using cleaners and disinfectants. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Designated parking areas are established for visitor and employee vehicles. | ||||

| 2. Designated farm vehicles are used to transport visitors when possible. | ||||

| 3. Vehicles, tools and equipment are assessed for risk and, if necessary, inspected for soil, plant debris, organic material and insects and cleaned prior to entry and movement between production areas or designated areas. | ||||

| 4. The entry of recreational vehicles onto the premises and especially into production areas is restricted. |

3.3.5 OutputsFootnote 12

Target outcome:

- Product leaving the farm operation is free of pests of concern.

- By-products or waste are disposed of or treated to reduce the risk of spreading pests.

Outputs can be categorized into two distinct types:

- The final product, which should be free from pests of concern.

- By-products or waste, which may contain pests and require specific treatments or disposal methods to mitigate the risk of pest spread.

Both types of outputs pose a risk of pest introduction or spread to the areas surrounding your farm, neighbouring farms or other regions.

Benefits

Managing outputs mitigates the risk of infesting or re-infesting your farm, as well as infesting neighbouring farms, other crops and the environment.

Complete the following checklist to assess existing biosecurity measures at your farm or identify new biosecurity measures that should be incorporated into your biosecurity protocols. Indicate with a checkmark whether each biosecurity measure is:

- Yes (Y): Already in effect at your farm in all situations where it is appropriate.

- Sometimes (S): In effect, but not in all situations where it would be useful; would benefit from additional attention.

- No (N): Not in effect in any situation.

- N/A: Not applicable at your farm.

3.3.5 Biosecurity measures: Outputs

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. The pest status of the region(s) receiving the product is known. | ||||

| 2. The pest regulations for the intended market are known to ensure the final product meets phytosanitary certification requirements. | ||||

| 3. During the growing season and at the time of harvest, the farm and/or harvested crop are monitored for the presence or symptoms of pests. | ||||

| 4. Established industry protocols for testing, labelling and segregating final product are followed (e.g. salt solution, brown sugar solution or hot water procedures to test for presence of fruit fly larvae). | ||||

| 5. Grading, packing and labelling are conducted in a designated area away from production areas. | ||||

| 6. The final product is identified and labelled to allow for traceability in the event of a pest detection. | ||||

| 7. The Plan is communicated to customers. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Infested pruning debris is removed from production areas or destroyed. | ||||

| 2. Culls and fruit and nut waste are managed or disposed of by deep burial, transportation to a municipal disposal or composting facility, or other method that minimizes the risk of pest introduction and spread. | ||||

| 3. Composting of infested material is conducted in a manner that minimizes pest risk, based on the biology of the pest (e.g. optimum temperature required to kill the pest is reached). | ||||

| 4. Compost and cull piles are located away from production areas. | ||||

| 5. By-products are transported in clean, leak-proof bins since juice may contain pests. |

3.4 Pest Monitoring Program and Response PlanFootnote 13

Target outcome:

- Minimize production losses through the early detection of pests.

- The evaluation of the pest risk is used to develop your response plan.

To develop a pest monitoring program and response plan (including an emergency response plan) for your farm, there are four steps to follow:

- Know the pests you need to monitor for.

- Develop the monitoring program and response plan.

- Implement the monitoring program and response plan, and keep accurate records.

- Reassess the monitoring program and response plan.

Example: Pest risk assessment considerations for brown marmorated stink bugFootnote 14,Footnote 15

Brown marmorated stink bug (BMSB), Halyomorpha halys, is native to Asia and has established large populations in the United States, where it is considered a significant agricultural and nuisance pest. BMSB is an excellent hitchhiker and can be moved over large distances in shipping containers, cargo and vehicles. BMSB is established in parts of southern Ontario and is expected to continue spreading.

BMSB has a very broad host range that includes tree fruit, berries, grapes, vegetables, agronomic crops, ornamental trees and ornamental shrubs. It is highly mobile and can readily switch hosts, moving between crops throughout the growing season. Crops bordering woodlots are at the highest risk of attack.

Infestations have not been detected in crops in Ontario. There are several insecticides registered for use against BMSB in Canada; however, action thresholds are not available for most crops. Biosecurity measures targeting this pest could include trapping to ensure early detection, control of vehicles arriving from infested areas, and cleaning of infested indoor areas.

Benefits

Developing and implementing a pest monitoring program and response plan allows you to be proactive rather than reactive. Pest monitoring supports the early detection and identification of pests in your farm, which gives you more options for pest management and control, such as using cultural or biological controls as part of an Integrated Pest Management (IPM) program.

The benefits of early pest detection and response outweigh the costs of controlling serious pest infestations and include:

- Consistently high yield and reduced crop losses from pest infestations.

- Improved crop quality.

- Fewer restrictions on access to markets.

- Lower pest management and production costs.

- Increased customer confidence.

- Easier processing of product.

Example: Response plan considerations for blueberry scorch virusFootnote 16

Blueberry scorch virus (BBSV) is spread by aphids and should be monitored for at bloom time. If symptoms appear, the plant should be flagged and a sample sent to the provincial ministry of agriculture for identification. If it is BBSV and is found during bloom, the plant should be removed from the field and, if aphids are present, an aphicide should be applied after the bees have been removed from the field. If BBSV is found outside of the bloom period and aphids are present, the aphids should be controlled first and the plant then removed from the field.

Complete the following checklist to assess existing biosecurity measures at your farm or identify new biosecurity p measures that should be incorporated into your biosecurity protocols. Indicate with a checkmark whether each biosecurity measure is:

- Yes (Y): Already in effect at your farm in all situations where it is appropriate.

- Sometimes (S): In effect, but not in all situations where it would be useful; would benefit from additional attention.

- No (N): Not in effect in any situation.

- N/A: Not applicable at your farm.

3.4.1 Biosecurity measures: Gathering information

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Information sources such as provincial government bulletins, production guides, industry association communications, crop reports, field guides, industry internet resources, and local and international newsletters are reviewed regularly. | ||||

| 2. Information is gathered on new and potentially high-risk pests that are emerging as a threat to the industry in other facilities and/or countries. | ||||

| 3. The relative risks associated with pests of concern are understood and high-risk pests are prioritized for monitoring and development of response plans. |

3.4.2 Biosecurity measures: Pest monitoring

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. The pest monitoring program is designed to detect both pests that are familiar to farm staff and new pests that have rarely or never previously been found on the farm. | ||||

| 2. The appropriate monitoring protocols for specific pests are known and used. | ||||

| 3. Monitoring protocols are designed based on the life cycle of the pests, including stages of development, where they are found and symptoms. | ||||

| 4. Monitoring is conducted at appropriate times and frequencies, since some pests are more active in the morning or at night, or during certain times of the year. | ||||

| 5. Areas on the farm that should be monitored for pests, such as fields, packing sheds and shipping and receiving areas have been identified. | ||||

| 6. New plants are inspected when brought onto the farm and are continuously monitored for pests. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. The pest monitoring program has been implemented in the production areas and in the farm buildings. | ||||

| 2. Monitoring results are recorded and records are maintained. | ||||

| 3. Staff have been identified and trained to conduct the monitoring program. | ||||

| 4. Employees have been informed to report all unknown symptoms or pests to their supervisor. | ||||

| 5. In farms where imported and domestically sourced product is packed and repacked, posters of pests of concern are placed in the packing area to help employees identify pests when inspecting material. | ||||

| 6. The monitoring program is reviewed and assessed, and the dates of these reviews are recorded. |

3.4.3 Biosecurity measures: Response plan

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Samples are kept to help correctly identify the pest. | ||||

| 2. Laboratories, extension specialists, researchers and the Canadian Food Inspection Agency (CFIA) are contacted to confirm the identity of the pest. | ||||

| 3. If the regulatory status of the pest is unknown, the CFIA, provincial government or industry association are contacted for confirmation. | ||||

| 4. If an unfamiliar pest is detected, industry organization(s) are contacted to determine the risk and appropriate response plan. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Response plans have been developed and communicated for known pests. | ||||

| 2. The response plan is assessed and revised on a regular schedule and following pest outbreaks. | ||||

| 3. Action thresholds for specific pests have been determined. | ||||

| 4. The pathways of transmission for pests of concern are known and biosecurity measures are applied to probable pathways to contain to the infestation. | ||||

| 5. Farm operations are performed in an order that avoids spreading pests from the infested area, e.g. mowing the infested area last. | ||||

| 6. Locations and dates of pest finds are recorded, since this can inform the monitoring program. | ||||

| 7. Effective cultural and/or biological controls are identified. | ||||

| 8. If pesticides are used, ways to prevent pests from becoming resistant are considered (e.g. regular rotation of sprays). | ||||

| 9. Timing and conditions of pesticide application are effective. | ||||

| 10. Detailed spray records are kept and are available for review. | ||||

| 11. Pest control actions are assessed and revised as needed. | ||||

| 12. An appropriate disposal method for infested material is chosen based on the pest's pathway of transmission (e.g. for pests spread by wind, dispose of by deep burial or transport off-site to a municipal landfill). |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Infested areas are visually identified using signs and/or flagging tape. | ||||

| 2. Employees are notified of the locations of the infested areas. | ||||

| 3. Vehicles and equipment are inspected and cleaned upon exiting the infested area to prevent spread of the pest. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. The CFIA is informed of the pest find. | ||||

| 2. The response measures specified by the CFIA are implemented. |

4.0 Communication, Education and TrainingFootnote 17

Target outcome:

People entering or working within your farm operation respect the biosecurity measures in place.

The biosecurity measures in your plan should be communicated to employees, visitors and neighbours.

Employees need to be informed of the Plan and also given training and education to properly implement the biosecurity measures in your Plan. Employees should be invited to provide input on the Plan, as they will take more ownership of the Plan and will be more likely to implement the biosecurity measures.

Visitors may not be familiar with the biosecurity measures in place at your farm and could introduce pests from outside your farm or spread them between areas within your farm.

Your Plan should be communicated to your neighbours, since their activities may increase the pest risk to your farm (e.g. cultivating pest host plants) or interfere with your biosecurity measures (e.g. spraying pesticides that impact your beneficial insects). See also section 5.0 Site Assessment: Geography, Location and Layout for more information on this topic.

Example: Integrating biosecurity into your employee trainingFootnote 18

In addition to topics such as food safety and occupational health and safety, training on biosecurity can be included in orientations for new employees.

| Employee practices | Training completed | Assessment completed |

|---|---|---|

| Eat only in designated break areas. | X | X |

| Wash hands after breaks and using the bathroom. | X | X |

| Clean and disinfect tools before moving to a different production area. | X | X |

Example: Communicating with your neighbours about biosecurityFootnote 19

If your neighbor has a fruit tree in their backyard that could potentially be a host for pests of concern for your crops, you might offer to pay for removal of the tree and, in exchange, offer them free fruit from your farm.

Benefits

Communication, education and training help ensure that employees and visitors understand the importance of biosecurity and implement your biosecurity measures effectively. They also reduce the potential biosecurity risks posed by your neighbours' activities.

Complete the following checklist to assess existing biosecurity measures at your farm or identify new biosecurity measures that should be incorporated into your biosecurity protocols. Indicate with a checkmark whether each biosecurity measure is:

- Yes (Y): Already in effect at your farm in all situations where it is appropriate.

- Sometimes (S): In effect, but not in all situations where it would be useful; would benefit from additional attention.

- No (N): Not in effect in any situation.

- N/A: Not applicable at your farm.

4.0 Biosecurity measures: Communication, education and training

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Biosecurity measures and information regarding pests of concern are included in the training program. | ||||

| 2. Employees are invited to provide input into the development and implementation of the Plan. | ||||

| 3. Signs, measures and the Plan are in the language(s) of employees. If this cannot be done, the information is communicated effectively to employees in a way that addresses language barriers. | ||||

| 4. The Plan is always accessible to employees. | ||||

| 5. The farm manager ensures that employees understand the biosecurity protocols. | ||||

| 6. The farm manager ensures that employees implement the biosecurity protocols. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Signs are used to inform visitors of relevant biosecurity measures that must be adhered to. | ||||

| 2. Visitors are informed of the biosecurity measures upon arrival by an employee. | ||||

| 3. Visitors are accompanied by an employee to ensure that farm biosecurity protocols are followed. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Biosecurity protocols are communicated to your farm's neighbours. |

5.0 Site Assessment: Geography, Location and LayoutFootnote 20

Target outcome:

Use knowledge of geography, location and layout to plant new sites and to protect existing or neighbouring sites.

Geography (e.g. elevation, topography, drainage), environmental factors (e.g. water availability and wind direction), location and layout can influence the risk of pests being introduced into your farm from the surroundings and of spreading between areas within your farm. These factors are important points to consider when developing your Plan, although some pathways of transmission are more easily managed than others. Pathways such as wind, water and wildlife, for example, can be difficult to control.

These factors should be considered when selecting the site of a new farm. For existing farms, they should be considered when developing the farm's Plan and when there is an opportunity to change the layout of the farm (e.g. establishing new fields).

It is important to identify areas where you need to apply specific biosecurity measures. This may include areas that are designated for certain higher-risk activities, such as receiving and inspecting inputs, cleaning equipment, disposing of infested material, etc.

Benefits

Understanding the pest risks from the area around your farm can help you develop and implement biosecurity measures to reduce the risk of pest introductions into your production areas. Planning the layout of the various types of areas in your farm with biosecurity in mind can help reduce the risk of pests moving from potentially infested areas, such as disposal sites, into production areas, particularly those with higher-value crops or crops that are more vulnerable to pest incursions. This can help prevent pest infestations from spreading within your farm, reducing the impacts of pests and the cost of controlling them.

Complete the following checklist to assess existing biosecurity measures at your farm or identify new biosecurity measures that should be incorporated into your biosecurity protocols. Indicate with a checkmark whether each biosecurity measure is:

- Yes (Y): Already in effect at your farm in all situations where it is appropriate.

- Sometimes (S): In effect, but not in all situations where it would be useful; would benefit from additional attention.

- No (N): Not in effect in any situation.

- N/A: Not applicable at your farm.

5.0 Biosecurity measures: Site assessment

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. Any available provincial or regional biosecurity strategies are considered when developing your Plan. | ||||

| 2. The history and previous use of newly acquired or leased land is assessed for pests of concern and for potential build-up of chemical control products. | ||||

| 3. Neighbouring land uses (both operating and abandoned) that could be a source of pests are identified, e.g. nurseries, other commercial plantings, native vegetation, urban plantings, livestock and poultry farms, or certain non-farm uses (e.g. dump sites). | ||||

| 4. Management practices used on neighbouring sites are known, as they may impact your management strategies. | ||||

| 5. Potential host plants within and around production areas are identified and are removed or controlled. | ||||

| 6. Natural barriers such as roadways or neighbouring farm boundaries (e.g. windbreaks, hedges) are used to help control access to your site. |

| Biosecurity measure | Y | S | N | N/A |

|---|---|---|---|---|

| 1. A detailed map of your farm has been developed that shows the overall layout of the farm, including buffer zones. | ||||

| 2. Designated areas have been identified and are indicated on the farm map. | ||||

| 3. Designated traffic flow routes are indicated on the farm map. | ||||

| 4. Potential entry points for pests are identified on the farm map. | ||||

| 5. Production areas are kept separate from high-risk activities such as receiving and cleaning. | ||||

| 6. Production areas are located on sites that have a lower risk of pest introduction from wind, water and soil erosion. | ||||

| 7. Production areas are located away from neighbouring crops that may be potential hosts or pathways of transmission of pests. | ||||

| 8. Imported and domestically sourced product is received, inspected and stored in the packing facility, away from production areas. |

6.0 Conclusion

This Biosecurity Guide for Fruit and Tree Nut Producers, together with the document Developing Your Biosecurity Plan: The National Voluntary Farm-Level Biosecurity Standard for the Fruit and Tree Nut Industries, provides producers with tools to help develop and implement Plans for their farms. Using these documents supports a nationally consistent approach to biosecurity that helps mitigate the risks of pest introduction and spread across Canada's fruit and tree nut industries, protecting this sector valued at over $840 million in 2014Footnote 21.

Producers are encouraged to regularly assess the effectiveness of their Plans, such as during the cycle of pre-season activities, and to routinely make updates and improvements to the biosecurity measures in place at their farm. Farming is your business – biosecurity supports a sustainable future for your farm.

Appendix 1: Example of a Pest Introduction Pathway Analysis

Note: This list of pests is not exhaustive and is intended as an example only.

| Plants | Soil, mulch | Air, wind | Water | People | Other pathways | |

|---|---|---|---|---|---|---|

| Viruses | X | aphids, bees | ||||

| Botrytis blight, gray mould (Botrytis cinerea) |

X | X | X | |||

| Bacterial blight (Bacillus subtilis) |

X | X | ||||

| Mummy berry (Monilinia vaccinii-corymbosi) |

X | X | X | X | bees | |

| Armillaria root rot (Armillaria spp.) |

X | X | X | |||

| Phytophthora spp. | X | X | X | |||

| Aphids | X | X | X | machinery | ||

| Spotted-wing drosophila (Drosophila suzukii) |

X | |||||

| Weevils | X | X | ||||

| Loopers, caterpilllars | X | X | machinery | |||

| Invasive weeds | X | X | X | X | birds, animals |

| Plants | Soil, mulch | Air, wind | Water | People | Other pathways | |

|---|---|---|---|---|---|---|

| Blueberry maggot (Rhagoletis mendax)Footnote 22 | X | |||||

| Brown marmorated stink bug (Halyomorpha halys) |

X | X | X | |||

| Light brown apple moth (Epiphyas postvittana)Footnote 23 |

X | X | fruit shipments | |||

| European grapevine moth (Lobesia botrana)Footnote 24 |

X | X | fruit shipments |

Appendix 2: Example of a Sign Used to Limit Access to Restricted Areas

Description for image – Example of a Sign Used to Limit Access to Restricted Areas.

A yellow biosecurity sign that has a picture of a stop sign in the middle. Above the stop sign, there is the statement "Do Not Enter". The word "Not" is underlined. Below the stop sign, there is the statement: "Biosecure Area. For permission to enter, call". There is a line provided to write a phone number. In the bottom left corner, there is the Canadian Food Inspection Agency's corporate signature (a Canadian flag and the name of the Agency in English and French). In the bottom right corner, there is the Canada wordmark (the word Canada with a small Canadian flag above the last "a").

Appendix 3: Acknowledgements

- Agriculture and Agri-Food Canada

- British Columbia Blueberry Council

- British Columbia Cherry Association

- British Columbia Cranberry Marketing Commission

- British Columbia Fruit Growers' Association

- British Columbia Ministry of Agriculture

- Canadian Horticultural Council

- Food Processors of Canada

- Grape Growers of Ontario

- Ministère de l'Agriculture, des Pêcheries et de l'Alimentation du Québec

- Ontario Berry Growers Association

- Ontario Hazelnut Association

- Ontario Ministry of Agriculture, Food and Rural Affairs

- Ontario Tender Fruit Growers

- Perennia Food & Agriculture Inc.

- Producteurs de pommes du Québec

- Society of Ontario Nut Growers (SONG)

- University of Guelph, Berry and Tree Nut Research

- Wild Blueberry Grower Association of New Brunswick

- Date modified: